| The K1 Knobs

are Ready for Shipment! Three Finishes to Choose From! |

|

| The TS-830S shown above is

sporting a new K4EAA K1 Knob in original Kenwood Bronze!

After 6 months and a lot of trials, tribulations, dollars and

frustrations, I finally have a knob to be proud of, one that captures

the spirit and quality of the original KB-1 - If not exceeding it in

tolerance and finish! You can read about the features below, as

well as seeing movies as we worked out the machining steps necessary to

produce this beautiful Spinner knob. The anodizing is top rate,

and took six months to get it right

on. Processes, chemicals, and restrictions have changed

quite a bit in 35 years, especially in this country. It was

tough to match the original Japanese finish with the new regulations,

but we did it! Here's my early email feedback: "Ken, "I received my new knob from you today! It is as nice as you said! Thanks for all your hard work on it! I hope you sell enough to recover your costs plus a lot more! I will do all I can to get the word out! 73, Keith W8GX" "Ken; The knob arrived today ... it is gorgeous. Can you imagine a TS-830 with every knob this bright silver? I can ... it would be AWESOME! Chris, WD1W" An Update from Tom - "Having used the K1 tuning knob every

day for the past few weeks, I have nothing but praise for your efforts

and finished product. "Hi Ken, the knob arrived quickly. It works perfectly with my TS-830S and the tuning is smooth and very pleasant; cosmetically is beautiful and well finished and the color is right. Your hard work has really given a good result . Why don't you assign a serial number to the knobs? This increases the value of the same and also of the equipment. 73' Marco I1GTE" "Hi Ken - The new knob arrived Saturday (another record-breaking shipping speed! Thanks.). I ordered the dark, shiny bronze style. Fabulous doesn’t do it justice – the 830S is a dream to just tune around now. Amazing how much difference just changing a knob can make. I love the thing and appreciate the effort you put into it. 73, Bill K4EBE"

|

"Hi Ken - Just wanted to say thanks for the beautiful Knob. Came today and looks great, Steve, KU3S" "Hi Ken - I just got the knobs and I can not believe how nice they are. I would buy one to put on a shelf if I didn't have the Kenwood. What a great job packing, labeling and care instructions. Need I say more? Rudy KB3UAY "Hi Ken, Received the beautiful knob today Wednesday. It exceeded my expectations in every way. Tuning the dial is a pleasure and it's much more stable in selecting a frequency especially on SSB. I like it a lot. Thank you and 73, Richard K1IEE" |

|

| This knob features a weight of over 1/4lb., made from a solid billet of 6061-T6 aircraft grade aluminum. It is beautifully machined and bead blasted to a satin finish, and then professionally anodized by Florida's leading precision anodizer facility. The bright metal highlights on the top surface of the knob are then re-machined to reveal the underlying 6061. A similarly machined 6061-T6 spinner is suspended by a stainless steel ball bearing assembly to provide the ultimate finger spinner ever produced! |

|

| Using modern machining fixtures I was able to eliminate the deep channel machined into the base, required to hold the knob for front machining operations 35 years ago. The solid back leaves more aluminum for a heavier flywheel effect than the original. This knob will fit the TS-820, TS530, and TS-830 series of transceivers. The original KB-1 would not fit the TS-520 series, likewise the K1 will not fit properly on a TS-520. However, in the next production run, a K2 will be introduced specifically for the 520 series! This new K2 will have a recessed pocket to accommodate the bushing that protrudes on a 520 or 520S behind the knob. |

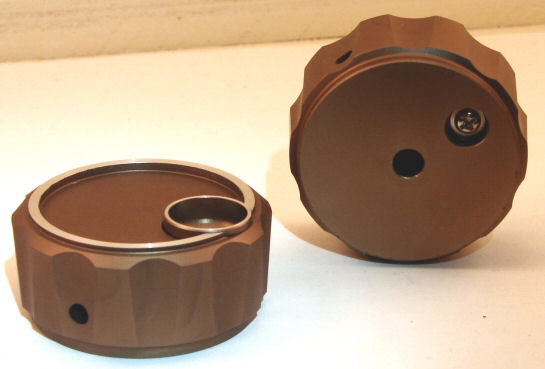

Shown Below in

Dark, Shiny Bronze Anodize |

|

Shown Below in CLEAR Anodize  |

| I just could not capture the actual color and shininess exactly in these photos - As one testimonial said, "The pictures don't do them justice." The dark Bronze is quite shiny and noticably darker than the front panel. The original Kenwood Bronze is lighter than the front panel. |

| PRICING AND AVAILABILITY |

| The K1 Series of knobs is now sold out - Anodizing problems have made them very hard to make, and I'm not too sure I want to spend any more time or money making more. Hopefully by now, everyone who ever wanted one, now has one. Those who purchased one should find their investment has doubled or tripled in value. Thanks to all who supported this effort. 73, Ken |

How We Made the K4EAA K1 Knob

|

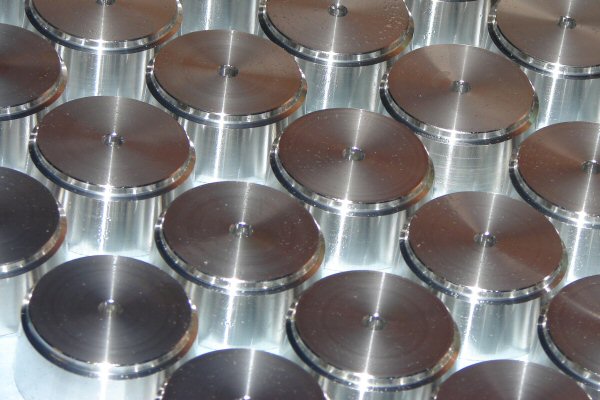

KNOB

BLANKS

We have begun the making of the knob bodies themselves. Here are some completed tapered knob blanks ready for the next operations. This is the bottom of the K-1, with LOTS of heavy 6061 T6 Aircraft Aluminum left for the desired flywheel style weight. Looking at these beauties, the color and finish possibilities seem endless! |

|

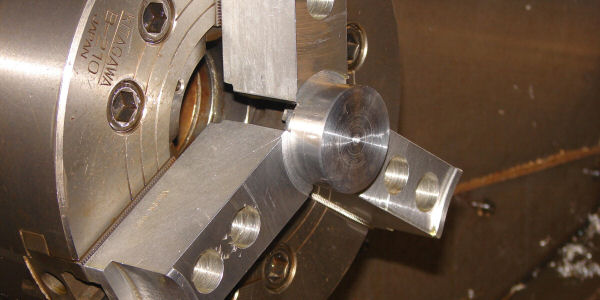

Watch a Movie of the knob blanks being drilled, reamed, faced and tapered This shows a BIG machine precisely cutting a 2-1/2" x 12 foot solid billet of 6061 T6 Aircraft Aluminum into tapered K1 knob blanks. As in the SC-M2 video, the flood oil has been turned off, so we're cutting dry here. Ordinarily, a waterfall of oil would be splashing over the part as it is machined. With the door open for filming, that's not a good idea . . . I have a blooper I'll try to link up here that shows an unexpected gusher!  Download KnobBlank WMV File 38 MByte 640x480 |

|

KNOB TOPS DONE!

This photo shows the tops of the knobs

completed with the nice bevel and shoulder, as found on the originals.

They are rather oily in the photo, but that oil assists the cutting tool in obtaining a startlingly nice surface finish! This first machining and anodizing cycle will provide a limited number of finished knobs - Actually, about as many as I could afford to make at one time! I am maintaining a queue, and your early (non-binding) order requests are being preserved. |

|

| Movie of

the Machining of the Front Face This movie shows the front face of the knob being machined with the recess and the ridge being formed, as well as the nice taper on the outer front edge of the knob. The oil flood has been turned off so we could leave the machine door open for recording. When they are being made under full CNC control, there is a huge bath of oil constantly pouring over the material.  Download KnobTop WMV File 45 MByte 640 x 480 |