Kenwood Hybrid Band Switch Repair

by Ken, K4EAA

|

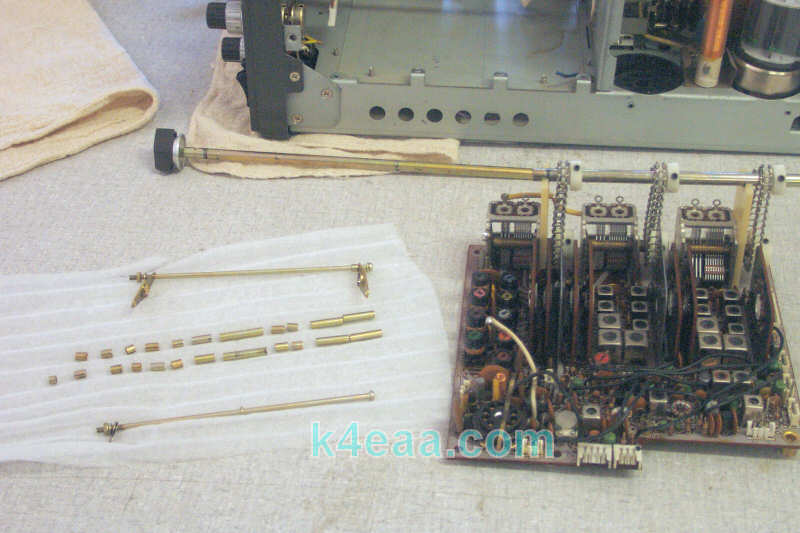

There's a small but persistent number of TS-530S's and TS-830S's that develop bandswitch problems. Like everything else in the Kenwood Hybrid lineup, these can be repaired fairly easily by most Hams. 90% of bandswitch problems can be corrected with a simple cleaning with contact cleaner/lube, but occasionally a deeper repair is necessary. The bandswitch wafers are PC boards with switch contacts riveted to the copper traces on the board. Sometimes, corrosion prevents a good contact between the copper traces and the riveted contacts. The only real solution is to remove the wafers so they are accessible, and then use conductive ink to bond the contacts positively to the copper. The conductive ink is composed of pure silver spheres that are approximately 10 microns in diameter. The tiny silver spheres are contained in a slurry that consists of binders and solvents. When applied to a circuit board, the solvents evaporate and bind the silver particles to the substrate they are applied to, effectively electrically connecting the metal contact areas. This is a very effective repair, one that can restore full functionality to your rig. The biggest problem facing you is getting to the contacts that require testing and bonding. Here is a step-by-step procedure, with some photos taken during a recent restoration of a customer's rig with bandswitch problems. First of all, the RF board must be removed. This is accomplished by unplugging all the connectors to the RF board, unsoldering 3 wires on the 830S (2 on the 530S), removing the hold-down screws, and removing the bandswitch shaft. To get the bandswitch shaft out, you have to first open the final compartment, and discharge any voltage on the HV caps by shorting an insulated-handle screwdriver between the chassis and the top of the plate choke (where the 6146 plate caps connect to). THIS IS IMPORTANT, DON'T SKIP THIS STEP!! If High Voltage is present, it could kill you, as in Silent Key! Remove the 6146 closest to the front of the rig as shown in the photo. This exposes the bandswitch coupler located in the final compartment. Using a 1.5mm (0.050") Allen wrench, loosen the two setscrews at the front of the coupler. The knob with shaft attached can now be removed from the front of the radio. Pull it straight out, leaving all the switch wafers aligned relative to one another! You don't want to get any wafer 180 degrees out of phase! Loosen all the setscrews on the DRIVE coupler, and slide the coupler back so the board can be removed. Remove the 12BY7A with its shield, and slide the RF board straight out the side of the rig. If you feel any obstruction, stop - You may have forgotten to disconnect something, as it comes out quite easily if properly disconnected from everything. You can see the RF board removed from the 830S in the picture below. |

|

Next, you have to disassemble the bandswitch hardware. This consists of two long screws that extend through all the bandswitch wafers with spacers to keep the wafers aligned relative to each other. Re-assembly is easiest if you keep the spacers organized as you remove them. You can see the spacers arranged to the left of this next photo in the order they were removed. I use a pair of narrow forceps I bought at a flea market for $1 to hold the spacer while I slide the screw out |

|

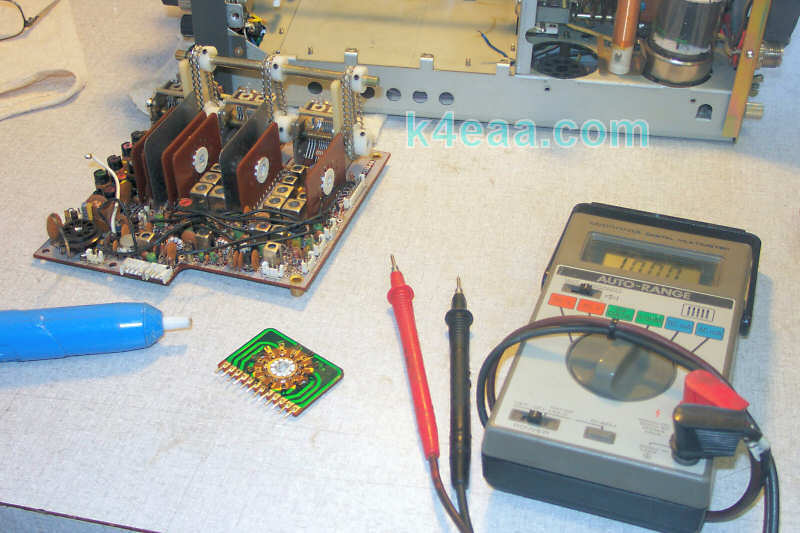

Now the switch wafers have to be removed, so you can measure and repair them. This is best done one wafer at a time, so you don't get them out of order. Use a good solder sucker to remove the solder at each pin, and they will simply fall out. NOTE AT THIS TIME WHAT GENERAL DIRECTION THE SWITCH CONTACT IS POINTING! You want to restore it to this approximate position when you are re-assembling, so all wafers will be "in sync" when completed. There is a notch in the plastic on the rotary portion of the switch, if you observe this and re-assemble them all the same with regards to the notch, it will serve the same purpose. Manually move the rotary portion of the switch to each position and measure the resistance at the pins for the position being tested. On the typical DVM this should be zero to 0.1 ohms after lead resistance is subtracted. You'll get a feel for what's normal after you measure a few. Any higher measurements than that call for a repair. You can also carefully bend the contacts in to get more contact pressure if needed. I use my fingernails for that. If that doesn't do it, it's probably the riveted connection that's not making good contact. |

|

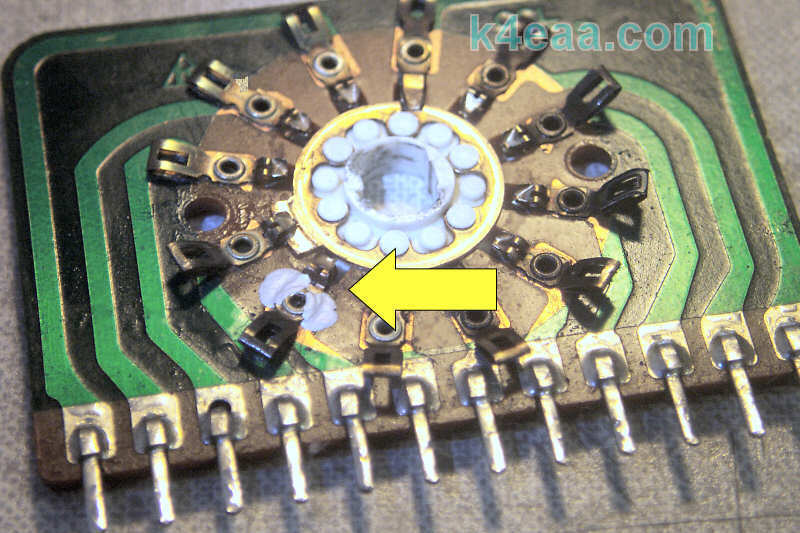

If you've gone through and cleaned, lubed, and squeezed the contacts together, and you still get high resistance, it's almost assuredly the contact between the pc board copper foil, and the riveted switch contact. First take your Xacto blade and scrape the metal on the switch contact, and the adjacent PC trace to get clean metal surfaces to bond to. Then take a solvent, alcohol or your choice, and clean the area you're going to apply the ink to with a Q-tip or similar. Get out your Silver conductive ink, shake well, and apply. If you have a bottle of ink, use a wooden toothpick or small brush to apply ink to the area needed to be bonded. If you use a conductive pen, follow the manufacturer's instructions. In the photo below, you can see how the silver ink has been applied so it positively connects the switch contact to the copper foil, both of which were scratched and cleaned. When done, you can bake at 150F for 5-10 min in your oven, to cure the ink and get a lower contact resistance (I cannot measure the difference with my meter, but it's a good idea in any event). |

After repairing the contact-to-board problems, simply reverse the above procedure to re-assemble. Good Luck!

|

|

|

|

|

|

|

Please Note: The above address is a

GIF image, to foil spammer robots.

You will have to type that address into your email client. Thanks

for your understanding, Ken.

All Photos and content copyright 2005, 2018 K4EAA, Ken

Kemski.